Silicone rubber is a versatile material with exceptional properties, including UV and chemical resistance, high-temperature stability, and flexibility. However, its low surface energy makes it one of the most challenging materials to bond. In this comprehensive guide, we’ll explore various methods, products, and expert tips on how to glue silicone together to itself, other polymers, and even metals.

Key Takeaways:

- Silicone is hard to bond due to low surface energy.

- Use silicone-based adhesives, primers with cyanoacrylates, epoxies, or UV-cured adhesives.

- Surface preparation, adhesive selection, and curing time are crucial.

Understanding the Challenge

Silicone’s low surface tension makes it hydrophobic and resistant to most adhesives. It’s often listed alongside polyethylene, polypropylene, and PTFE as one of the “impossible-to-bond” materials. But with the right techniques and products, you can achieve strong, durable bonds.

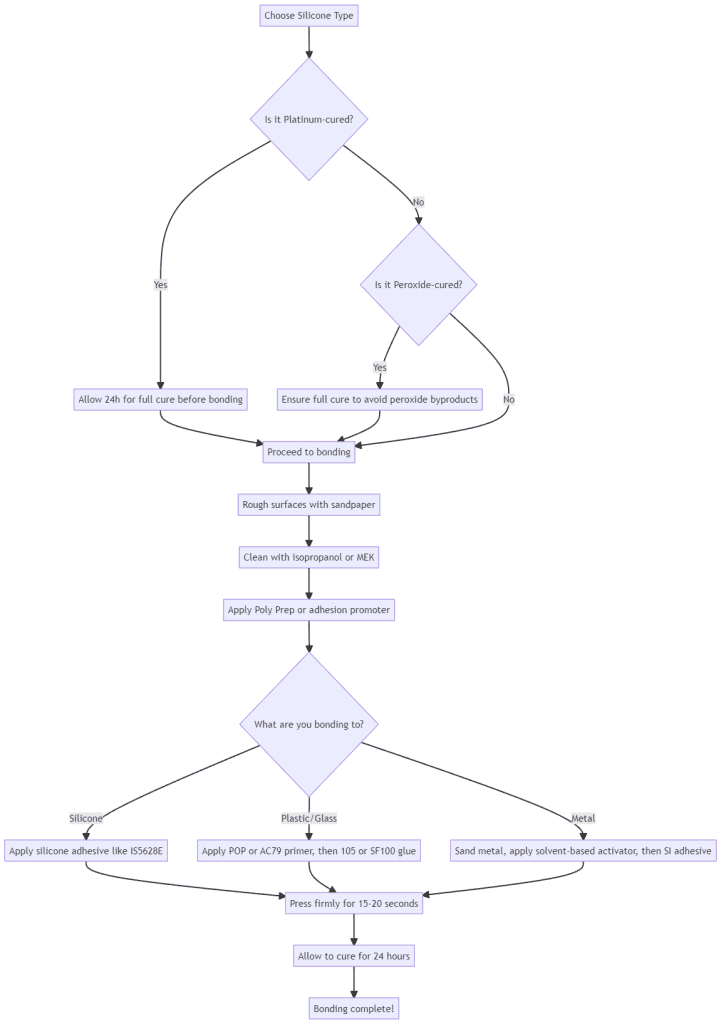

Diagram: Bonding Process for Silicone

Key Factors in Bonding Silicone

- Surface Preparation

- Adhesive Selection

- Pressure Application

- Curing Time

5 Methods and Products for Gluing Silicone

1. Silicone-Based Adhesives

There are 3 types of silicone-based adhesives:

a. RTV (Room Temperature Vulcanizing) Silicone Adhesives

- TSE397C, RTV108: Good for bonding silicone to itself without primer.

- IS5628E: Specifically designed for silicone-to-silicone bonding. Strong, flexible, and durable.

- DOWSIL™ 732: FDA-approved, acetic silicone sealant. Great for the food and pharmaceutical industries.

b. Heat-Curing Silicone Adhesives

- Addisil 6101, TSE3221S: Faster curing times and better joint design.

c. PSA (Pressure Sensitive Adhesive)

- PSA529 + SRC18 catalyst: Provides high strength within seconds. Great for gaskets and laminations.

2. Primer + Cyanoacrylate (Superglue)

- Loxeal Primer 7 + Loxeal 34: Good for small details, but not for high-quality or outdoor applications.

- PERMABOND POP + PERMABOND 105: Industry-proven solution for bonding difficult rubbers like silicone.

- 3M AC79 primer + 3M SF100 glue: Excellent for bonding silicone to zip rings in dry suits.

3. Epoxy Adhesives

- J-B Weld ClearWeld: A general-purpose epoxy that can bond silicone to glass or plastic.

- Loctite Hysol 1C: A white, room-temperature curing epoxy with excellent strength and chemical resistance.

4. UV-Cured Adhesives

- Loctite AA 349: Great for bonding silicone to glass or plastic, as it can cure through glass.

5. Specialty Products

- Sil-Poxy™: One-component adhesive specifically for bonding RTV silicone rubber.

- E6000: A clear silicone adhesive that can work on some types of silicone.

- Spikeez or Gel A Peel: Silicone goo that sticks to silicone, great for decorative purposes.

You Can Check It Out to Glue Felt Together.

3 Common Situations for How to Glue Silicone Together

Here are the most common situations for how to glue silicone together:

Situation 1: Bonding Silicone to Itself

- Rough the surfaces with sandpaper or steel wool.

- Clean with isopropanol or MEK (Methyl Ethyl Ketone).

- Apply Poly Prep or a similar adhesion promoter.

- Warm both surfaces to about 120°F (not hot).

- Apply silicone adhesive (like IS5628E) to one surface.

- Press firmly for 15-20 seconds.

- Allow curing for 24 hours for best results.

Situation 2: Bonding Silicone to Plastic or Glass

- Rough the silicone with sandpaper or steel wool.

- Clean all surfaces with isopropanol or MEK.

- Apply Poly Prep to the silicone.

- Apply PERMABOND POP or 3M AC79 primer to either surface.

- Apply PERMABOND 105 or 3M SF100 to the opposite surface.

- Press firmly for 15-20 seconds.

- For glass bonding, consider UV-cured adhesives like Loctite AA 349.

Situation 3: Bonding Silicone to Metal

- Rough the silicone with sandpaper or steel wool.

- Sand the metal to a near-white or polished finish.

- Clean all surfaces with isopropanol or MEK.

- Apply Poly Prep to the silicone.

- Apply solvent-based Activator/Accelerator to either surface.

- Apply SI Structural Adhesive to the opposite surface.

- Press firmly for a minimum of 15 seconds.

Special Considerations

1. Platinum-Cured Silicone

Allow 24 hours for the bond to cure due to ongoing chemical reactions in fresh silicone fully.

2. Peroxide-Cured Silicone

Ensure full curing before bonding to avoid interference from peroxide byproducts.

3. Decorative Applications

Use products like Spikeez or thinned silicone with glitter for creative designs.

FAQs About How to Glue Silicone Together

What Kind of Glue Works on Silicone?

Using a flexible cyanoacrylate adhesive like Permabond 2050 is effective when bonding silicone. Priming the silicone with a polyolefin primer and using adhesive promoters like Loctite 401 with 777 can further enhance the bonding process. Proper surface preparation and selecting the right adhesive are crucial for the successful bonding of silicone. It’s important to seek further information from adhesive manufacturers for the most suitable product for your application.

How Do You Bond Silicone to Silicone?

When bonding silicone to silicone, various methods can be used, including using a primer with cyanoacrylate glue, room temperature curing silicone adhesives, heat-curing silicone adhesives, PSA glue, or surface pretreatment like corona treatment. Each method has its application, and the choice depends on the specific requirements and properties of the silicone rubber being bonded. Ensuring clean silicone surfaces is crucial for successful adhesion.

How Do You Glue Broken Silicone?

When repairing a torn silicone seal in an aquarium, draining the tank and applying a new bead of aquarium-safe silicone sealant along the joints is essential. However, it’s crucial to be cautious of potential harm to the fish from silicone fumes during the repair process. Some members suggested that if the tear is not into the corner seam itself, it may not require repair, especially since the new silicone does not adhere well to old dry silicone. Ultimately, the decision to repair the tear depends on the extent of the damage and the risk of potential leaks.

How to Join Two Silicone Rubbers?

When joining two silicone rubbers, clean the surfaces with isopropanol and apply Permabond POP primer. Then, use Permabond 105 or 2050 cyanoacrylate adhesive for bonding. Keep in mind the time limit for bonding parts treated with POP and that POP primer increases the bond strength of cyanoacrylate bonds on silicone and other substrates. Following these steps and using the recommended products will help achieve a strong and durable bond when joining two silicone rubbers together.

Is Superglue Good for Silicone?

When it comes to bonding silicone rubber, there are options like cyanoacrylate adhesives such as Permabond POP or instant adhesives like 538 that can be used. The Permabond POP primer can enhance the bond strength for cyanoacrylate adhesives on materials like silicone, while the 538 instant adhesive bonds silicone rubber without the need for a primer. The 538 instant adhesive is known for its fast drying, high flexibility, strong bonding strength, and low odor, making it a suitable choice for bonding various materials including silicone rubber, ABS, EPDM, PVC, TPU, TPR, PA, and TPE.

Will Silicone Stick to Silicone?

Silicone can adhere to silicone surfaces. It’s essential to prep the surfaces by ensuring they are clean and dry to achieve optimal adhesion. Some silicone adhesives are specifically formulated for bonding silicone to silicone, providing a strong and durable bond. Following the product instructions is crucial for the best outcome. If you have a specific project in mind, feel free to share more details for further guidance!

Conclusion

Gluing silicone is challenging but not impossible. You can achieve strong, durable bonds by understanding the material, using the right products, and following the correct procedures. Remember that pressure, cleanliness, and curing time are as crucial as the adhesive choice. Whether you’re repairing a drysuit, creating a custom mermaid top, or working on an industrial project, there’s a solution for your silicone bonding needs.