PVC glue, also known as PVC pipe cement or CPVC cement, is a vital adhesive for connecting PVC pipes. However, a troublemaker situation arises when you go to use your PVC cement and discover it has dried out and become unusable. When unopened, PVC glue can technically last for 2-3 years if stored properly. However, once open, it tends to thicken and dry out relatively quickly without the proper precautions taken. Luckily, several straightforward storage tips can keep PVC cement fresh for extended periods. In this guide, we’ll discuss 10 tips on how to keep pvc glue from drying out usable for months or years.

Key Takeaways:

- Store PVC glue upside down or refrigerated to dramatically slow drying.

- Adding solvents can reconstitute thicker glue; tape threads to prevent air exposure.

- Avoid temperature extremes during storage; agitate before use.

- Follow the manufacturer’s storage recommendations.

- Replace glue once drying begins compromising bonds. Use safety gear when applying.

Understanding the Shelf Life of PVC Glue

Before we delve into storage techniques, it’s important to understand the concept of shelf life and how it impacts PVC glue. Shelf life refers to the period during which a product remains usable and effective when sealed and unopened. PVC glue typically has a shelf life of around 3 years from the date of manufacture, but it’s crucial to check the expiration date on the container for accurate information.

10 Essential Tips for How to Keep PVC Glue From Drying Out

Here are 10 tips on how to keep pVC glue from drying out:

1. Store the Glue Can Upside Down

One of the most effective ways to prevent PVC cement from drying out is to store the glue can upside down. Most cans utilize a plug of fresh glue in the tip/spout that creates an airtight seal when the can is inverted. Stored upside down with the cap tightly closed, PVC glue stored this way can easily remain usable for over 5 years.

2. Refrigerate the Glue Can

Refrigeration is another go-to approach for keeping PVC cement from drying and evaporating over time. The cool temperatures inside a refrigerator, typically 34-40°F, dramatically slow down thickening and keep compounds in a fluid state. Refrigerated PVC glue may last for decades without issue. Just be sure to let it slowly warm back to room temperature before using it to prevent application issues.

3. Use an Airtight Secondary Container

If you only need a small amount of PVC cement for a particular project, consider transferring some glue into a secondary smaller container that has an airtight lid/seal. Glass jars work great for this. Removing all air contact prevents the solvent compounds from evaporating and the glue from drying up. Close tightly after each use.

4. Add Extra Cement Solvent as Needed

If your PVC glue does begin to thicken up slightly from evaporation or minor drying out, you can add cement solvent to reconstitute it to the proper viscous consistency. Be careful not to over-thin the cement. Common cement solvents are tetrahydrofuran (THF), methyl ethyl ketone (MEK), and acetone. Have your safety gear on when using it.

5. Use Plumber’s Tape on Can Threads

To create an ultra-airtight seal on your PVC glue can, consider using the plumber’s tape (Teflon tape) on the threads before closing the cap tightly. This seals any gaps where air could seep in and cause drying. It also makes opening easier.

6. Avoid Temperature Extremes

When storing PVC cement glue cans long term, avoid areas with temperature extremes or direct sun exposure. This includes hot attics, garages, and storage sheds. The heat accelerates solvent evaporation. Freezing temps can also degrade compounds.

7. Agitate Well Before Using

If PVC glue does start to thicken slightly in storage, vigorously shake or stir the can to redistribute compounds evenly within the cement. This may thin it back out adequately depending on the level of drying that has occurred.

8. Use Within Shelf Life After Opening

Once open, try to fully use up PVC cement within 12-24 months. The shelf life shortens significantly compared to unopened cans. Mark your calendar when you first open and break the air-tight factory seal.

9. Ensure Proper Air Exposure When Using

When applying PVC cement glue to joints, it’s important to wait the specified time for solvents to evaporate and properly weld/fuse the pipe and fittings. This is usually around 5-30 seconds. Insufficient air exposure weakens bonds.

10. Check The Manufacturers Recommendations

Be sure to check the storage recommendations on your particular PVC cement brand’s packaging. Most manufacturers provide specifics on ideal storage temps, positions, and timeframes. Following their guidance is best to maximize shelf life.

You Can Check It Out to Remove PVC Glue From Hands.

Factors Affecting the Shelf Life of PVC Glue

Several factors can affect the shelf life of PVC glue, potentially leading to premature drying or degradation. Temperature exposure plays a significant role in the stability of PVC glue. It is essential to store the glue in a cool, dry place with temperatures ranging between 40 and 110 degrees Fahrenheit. Extreme temperatures outside of this range can cause chemical changes that reduce the effectiveness of the glue.

Another critical factor to consider is the proper closure of the container. When the glue is not in use, it’s crucial to seal the container tightly to prevent the evaporation of solvents. If the container is not closed correctly, air can enter, causing the glue to dry out quickly.

Proper Techniques for Opening and Closing PVC Glue

To ensure the longevity of your PVC glue, it’s essential to follow proper techniques when opening and closing the container. When opening a new container, use adjustable pliers or a pipe wrench to grip the lid firmly. Turn the lid counterclockwise until it can be removed.

When closing the container, hand-tighten the lid and then use adjustable pliers to tighten it to a fully closed position. It’s crucial not to apply excessive pressure or overtighten the lid, as this can distort the lid and compromise the airtight seal. By following these guidelines, you can maintain an airtight seal and prevent premature drying of the glue.

You Can Check It Out the PVC Glue Calculator.

Dry Fitting and Preparation

Before applying PVC glue, it’s essential to properly prepare the pipes and fittings for a secure bond. Begin by cutting the pipe according to your project design using a suitable cutting tool. For smoother edges, use a deburring tool or sandpaper to remove any roughness or burs from the cut ends of the pipe.

Before applying the glue, perform a dry fit by fitting the pipes and fittings together without any adhesive. This step allows you to ensure proper alignment, measurements, and angles before applying the glue. Remember that the receiving socket of a PVC pipe fitting is often tapered, making it slightly challenging to push the pipe in during a dry fit. Account for this tolerance in your measurements to avoid any issues later on.

How to Apply PVC Glue

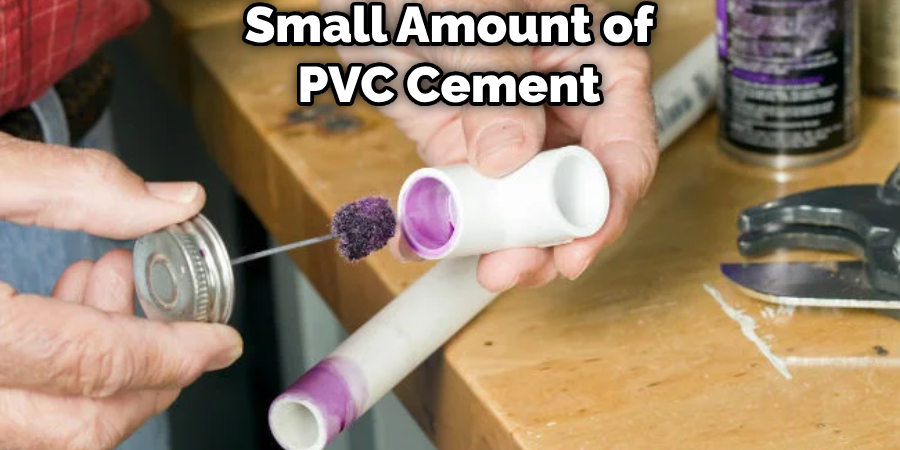

Once you have completed the dry fitting process and are satisfied with the alignment, it’s time to apply the PVC glue. Before applying the glue, it’s essential to use a primer specifically designed for PVC pipes. The primer prepares the surfaces, ensuring better adhesion and a stronger bond between the pipes and fittings.

Using the attached brush, apply a thin and even layer of primer to the outside of the pipe and the inside of the fitting. Ensure that the primer covers the surfaces completely for optimal results. Next, apply the PVC glue in the same manner as the primer, using the attached brush to coat the surfaces evenly. It’s crucial to work quickly but efficiently during this step, as the glue dries rapidly.

You Can Check It Out to Make Glitter Glue Dry Faster.

Assembling the Pipes and Allowing for Curing

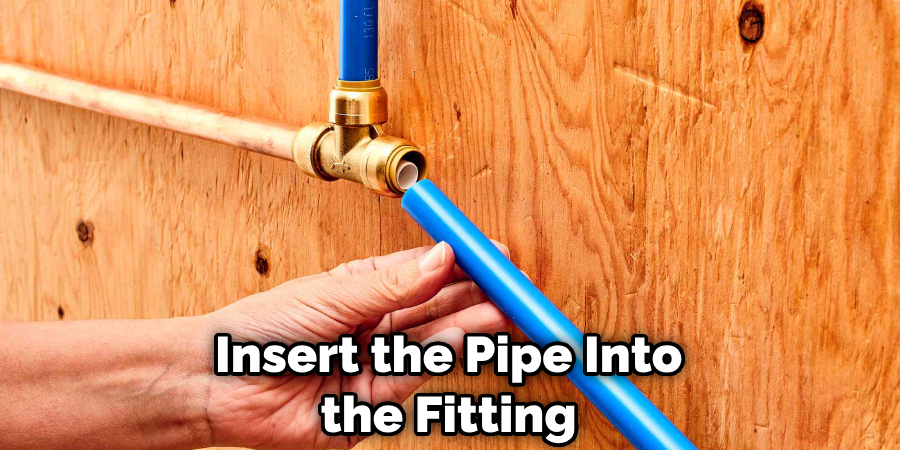

After applying the PVC glue, insert the pipe into the fitting, twisting it a quarter turn from its final position. This twisting motion helps to evenly distribute the glue and ensures a secure bond. Hold the pipe in place for at least thirty seconds to allow the glue to set.

Once you have assembled the pipes and fittings, it’s important to allow sufficient time for the glue to cure. While different brands may have varying curing times, most experts recommend leaving the glued joints undisturbed for at least twenty minutes before further handling or testing. For optimal results and maximum bond strength, it’s advisable to wait 24 hours before subjecting the joints to pressure or stress.

Safety Precautions When Working with PVC Glue

While working with PVC glue, it’s crucial to prioritize safety to prevent any harm or accidents. PVC glue contains solvents and should not come into contact with the skin or eyes. When working with PVC glue, always wear nitrile work gloves to protect your hands. Additionally, wear safety goggles to safeguard your eyes from any potential splashes or fumes.

Due to the release of toxins during the gluing process, it’s important to work in a well-ventilated area. If possible, use PVC glue in a garage or shed with open doors or windows to ensure proper airflow. If working in a confined space, such as a small room, it is recommended to wear a certified vapor-resistant mask or a respirator to minimize the inhalation of harmful chemicals. Lastly, it’s crucial to protect your work table or surface by covering it with a tarp or towel. PVC glue can be messy and may cause damage or stains if spilled or mishandled.

When to Replace PVC Glue

While it may be tempting to continue using PVC glue even after it has started to dry out or gel, it’s generally advisable to replace the glue with a fresh container. When PVC glue dries out, its effectiveness and bond strength may be compromised, leading to potential leaks or failures. Considering the relatively low cost of PVC glue, purchasing a new can when needed is recommended to ensure the best results.

FAQs About How to Keep PVC Glue From Drying Out

What is the Best Way to Store PVC Cement?

To store PVC cement effectively, ensure the container is tightly sealed to prevent evaporation, store it in a cool, dry place away from direct sunlight and heat, avoid freezing temperatures, store it upright to prevent spills, and always follow the manufacturer’s storage recommendations for optimal longevity and effectiveness.

Does Heat Make PVC Glue Dry Faster?

Heat can cause PVC glue to dry more quickly. Extreme heat conditions, especially above 90°F, can lead to a faster drying process for the PVC glue. However, it’s important to note that while heat can speed up the drying process, it can also cause the solvent cement to dry very quickly, potentially compromising the quality of the joint. Therefore, it’s essential to be mindful of temperature conditions when working with PVC glue.

Will PVC Cement Cure if Wet?

No, PVC cement will not cure properly if it comes into contact with water. The presence of water can interfere with the chemical bonding process of the PVC cement, preventing it from forming a strong and reliable joint. It’s crucial to ensure that both the surfaces being joined and the PVC cement itself are completely dry before application to achieve the best results.

Will Boiling Water Melt PVC Glue?

Yes, boiling water can potentially melt PVC glue. PVC glues are designed to soften and bond PVC surfaces with the help of a solvent, and exposure to high temperatures, such as boiling water, can cause the glue to soften, degrade, or even melt, leading to a loss of bonding effectiveness. Therefore, it’s important to avoid exposing PVC glue to extreme heat, including boiling water, to maintain its integrity and bonding capabilities.

Conclusion

Proper storage and usage techniques are essential to maintain the effectiveness and longevity of PVC glue. By following the guidelines outlined in this article, you can prevent premature drying and ensure a strong and reliable bond between PVC pipes and fittings. Remember to store the glue in a cool, dry place, seal the container tightly when not in use, and follow the recommended steps for applying PVC glue. By taking these precautions, you can achieve successful plumbing or crafting projects with PVC pipes while minimizing waste and maximizing the performance of your PVC glue.